Patterned conveyor belts, as a powerful assistant in modern industrial logistics, are designed in different types to better adapt to various complex transportation environments.

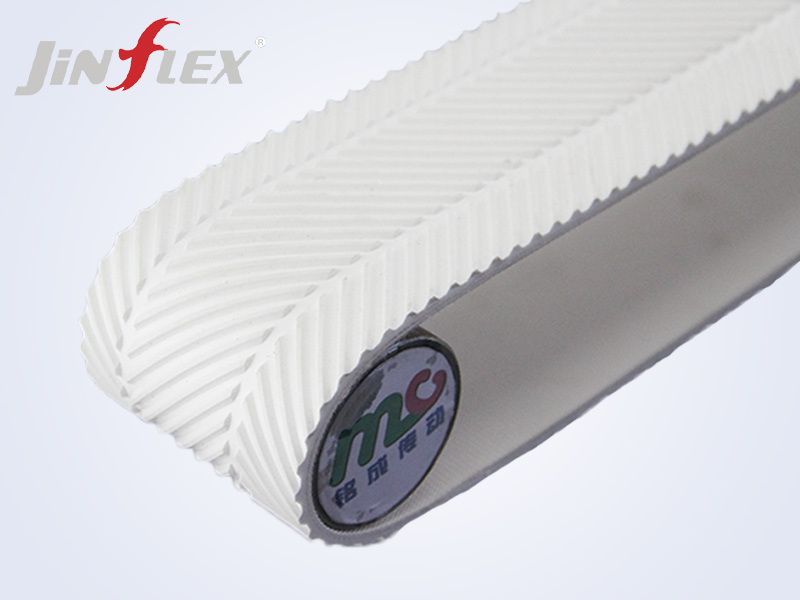

First of all, herringbone pattern conveyor belts are often used in slippery or watery workplaces, such as coal mines and cement plants, due to their high friction characteristics. Its unique “herringbone” design not only ensures the stability of the conveying process, but also reduces the risk of material slipping during conveying.

The herringbone pattern conveyor belt is more suitable for scenes with larger slopes and higher requirements for anti-skid performance. For example, in some mountain ore mining sites or material conveying lines with steep slopes, herringbone pattern conveyor belts can ensure the stability and safety of materials during transportation.

In short, different types of pattern conveyor belts have their unique application scenarios. The correct selection and use of patterned conveyor belts can not only improve transportation efficiency, but also ensure production safety and create greater value for the enterprise.

+ There are no comments

Add yours